New developments

New developments

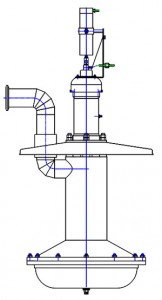

A feature of the centrifugal-vortex vibratory granulator is the possibility of self-cleaning of the basket holes when exposed to a high melt velocity gradient. With improved internal fluid dynamics and the use of an electromagnetic vibrator, this design allows the granulation of melts containing powdered additives such as calcium ammonium nitrate, NPK, etc.

This granulator passed industrial tests, showed good performance and quality of the granulometric composition on the float:

– ammonium nitrate with the addition of dolomite 20 … 25% at “HIP-AZOTARA”, Serbia, Pancevo (powder fraction 150 … 200 microns). The strength of the granules was 3.5 kg/granule;

– ammonium nitrate with the addition of phosphorus flour up to 30% at NavoiAzot. The strength of the granules was 2.5 kg/granule.

-ammonium nitrate with the addition of ammonium sulfate (nitrogen sulfate) at OJSC “AZOT”, Berezniki. The design difference of the rapidly rotating vibratory granulator from previously used standard types is a balanced combination of hydrostatic pressure of the volume of the melt and centrifugal force, which in total allows to significantly increase the flame irrigation, and the imposition of vibration ensures the disintegration of the jet into monodisperse drops and obtaining a high-quality finished product.

The granulator is installed at the urea production

JSC Gazprom Neftekhim Salavat