Compressors (turbines)

Compressors (turbines)

Depending on composition of gas to be sealed, dimension and mode parameters of compressor, the DGS unit may consist of one or several sealing stages. There is a number of lay out solutions of DGS units. The most common are the following: single seal, double seal «back-to-back», tandem.

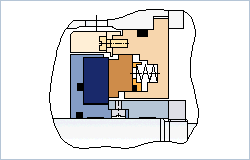

Single seal

The most simple seal consists of one sealing stage. It is applicable for sealing of non-hazardous and non-toxic gases with pressure up to 80 kg/cm². The seal may be completed with end labyrinth.

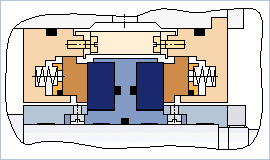

Double seal «back-to-back»

Consists of two sealing stages, located as per arrangement «back-to-back». Such arrangement is usually applicable in cases, where a vacuum can occur before sealing, or if an inert gas is used as a buffer gas in order to feed into the seal, leakage, of which, into compressor shall be minimized. Seal may be completed with end labyrinth.

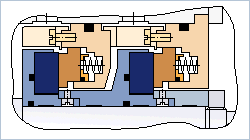

Tandem

Consists of two tandem sealing stages. Such lay out is the most common at compressors of chemical, petrochemical and natural gas industry, where hazardous and toxic gases are sealed. The seal may be completed with interstage and end labyrinth.

Materials (housing parts, sealing pairs, secondary seals etc.), applicable in DGS units shall be selected based on corrosion resistance of sealing environment.

Technical Spectifications:

– sealing pressure – up to 250 kg/cm²;

– temperature in seal area – up to 250 ºС;

– peripheral speed of rotating seat – up to 160 m/sec;

– shaft diameter under the seal – up to 300mm.

If any of these values are exceeded a special (nonstandard) seals may be applied.

Increasing of sustainability and durability:

– elimination the large number of complex and, as a consequence, unreliable equipment of sealing oil system (high pressure oil pump, units of oil seals with limited resource, differentioal pressure regulators, savealls, degasifier…);

– operating principle of basic elements (sealing pairs) and their construction features are such that they automatically respond to change of mode parameters of compressor operation and save their operability under emergency conditions even for the compressor arrangement therefore;

– loose connection of sealing pairs during operation eliminates tear-and-wear and increases operational life of the seal (more than 12 years).

Maintenance Benefits:

- in comparison with wet seals, there is no time-taking maintenance process (oil replacement, pump repair and associated equipment, whole system inspection);

- technical maintenance of dry gas seal systems include: visual inspection of working pairs, replacement of O-rings and tolerance strips (once in 1-4 years), replacemnt of clogged filter elements, periodic check-outs of instruments. Thus, maintenance is carried out with simple and easy to follow actions, being accomplished within a short period of time;

- assembly, disassembling, installation and dismantling of DGS units is very simple, and can be accomplished within a short period of time.