Installation of prilling systems

Installation of prilling systems

Preparation of supply lines.

1. Instrumentation air must be supplied 2÷6 kgf/cm2.

2. The supply of “live” steam to warm up the granulator before starting and stopping must

be carried out with a rubber pressure hose with a textile frame.

3. The supply of melt to the granulator must be carried out by a pipe (steel 12X18H10T).

4. Supply of electrical communications. An electric cable must be provided to power the granulator drive motor-reducer (380V, drive power 1.1 … 2.2 kW).

Installation option for granulators in rectangular towers (for example, AC-72 unit)

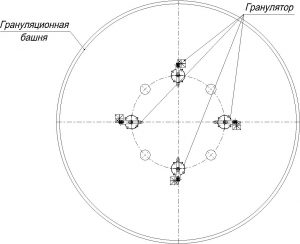

Installation of granulators in towers with no possibility of stopping the supply of melt (product) for a long time

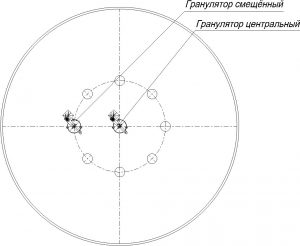

Options for installing a granulator in towers with a central air outlet

The classic installation scheme of the granulator

Installation of a granulator in towers with a central pressure manifold